Home » Products » Sampling and Injection Valves » Series IBA13

HYDROGEN READY

All valves are cleaned for oxygen and hydrogen

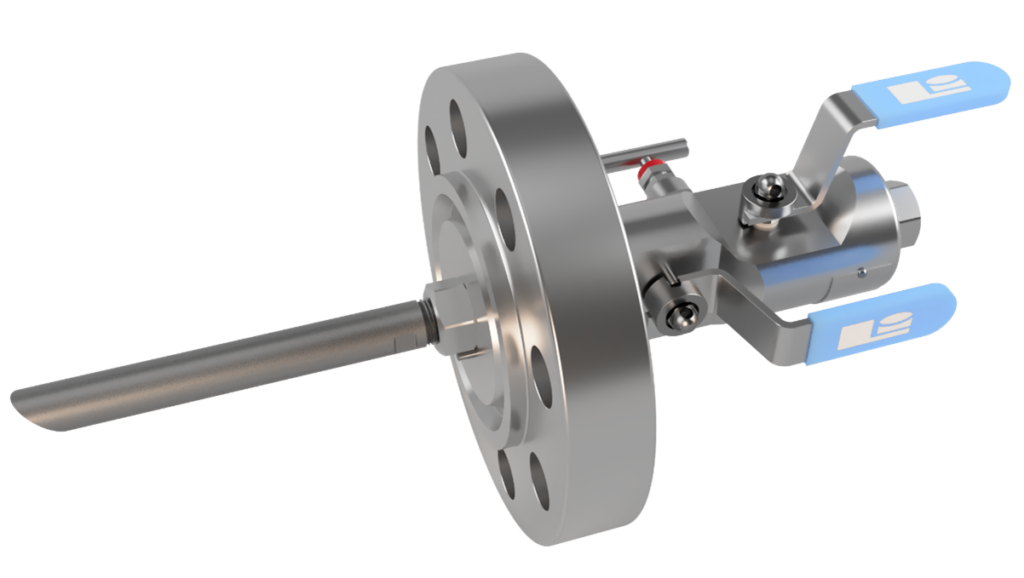

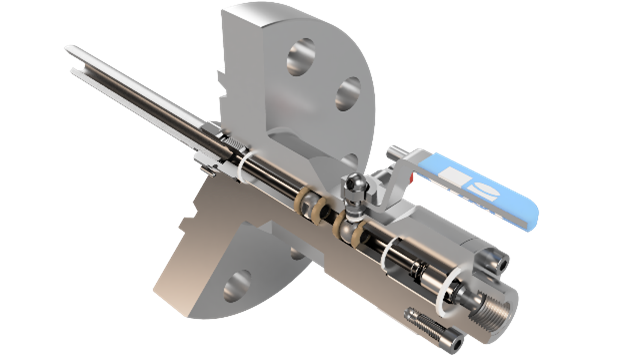

LIV DBB INJECTION BALL VALVE

SERIES IBA13

To API 6A flange.

- The valve body is machined from a round bar stock material

- or from forged material standard.

- The raw material of the valve can be supplied according to NORSOK M 630 or to customer´s specific requirements.

- The valve spindle is anti-blow out design with PTFE back seat gaskets.

- The injection valve has a ball with 10 mm bore.

- The balls are polished for low friction. The ball valves have PEEK seats.

- The process connection is flanged, and injection connection is

- ½” or ¾” NPT int. Quill sizes are ½” sch. 80 or sch. 160 and. ¾” sch. 80 or sch. 160.

- The handle has a plastic sleeve for protection.

- The dust covers are coloured for application indication (vent)

- The valves are designed for PED 2014/68/EU.

- Flange size: 2 1/16″ and 2 9/16″ type 6B

- Pressure rating: 3000 psi, 5000 psi

- Outlet connection: 1/2″ NPT int.

- Flange size: 1 13/16″, 2 9/16″, 2 9/16″ type 6BX

- Pressure rating: 10000 psi

- Material: AISI 316 (standard), A350LF2, 22Cr Duplex, 25Cr Duplex, 6 M0, Titanium, other materials on request.

- Packing: PTFE, PEEK

- Temperature: ÷40 to +260 ᵒC

- Operation: Handle, T-bar, or anti-tamper

- Coating: standard offshore, to customer’s spec., or none

- Material certificate to EN 10204-3.1 and 3.2

- Certificate of compliance to NACE MR 01-75 or EN 15156

- PMI test

- Pressure test certificate

- Fire safe tested acc. to EN 10497, API 607, BS 6755 part 2, ISO 5208

- Penetrant test on valve body to ASME BPV, ISO 3452-1 2021

- Fugitive emission to ISO 15848-1

The simple way to order

0

CHOOSE YOUR PRODUCT CONFIGURATION IN THE DATA SHEET

0

TYPE THE CODES INTO THE FORM AND SEND INQUIRY

0

FOR SPECIAL INQUIRIES, PLEASE REACH OUT TO OUR SALES TEAM